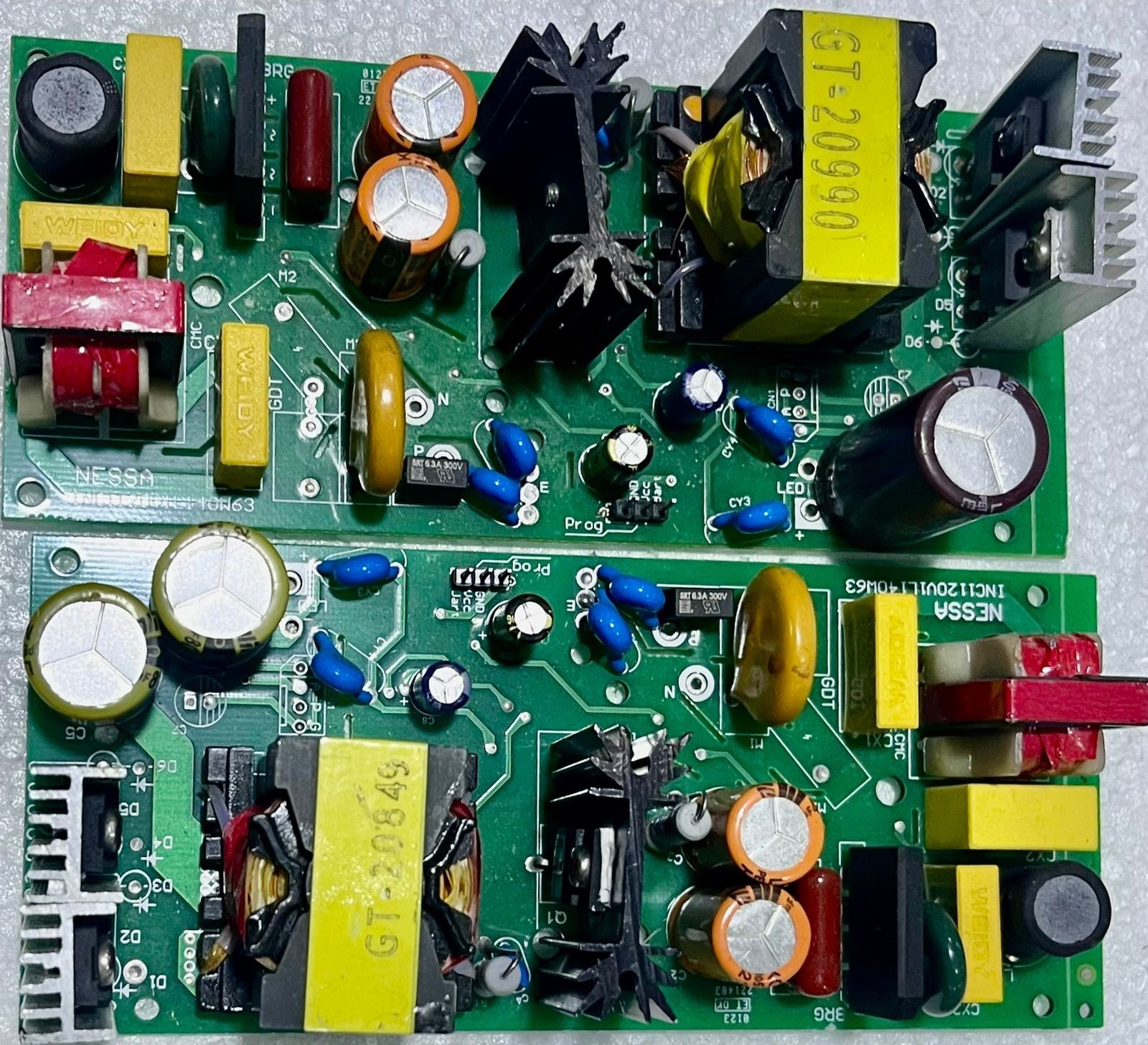

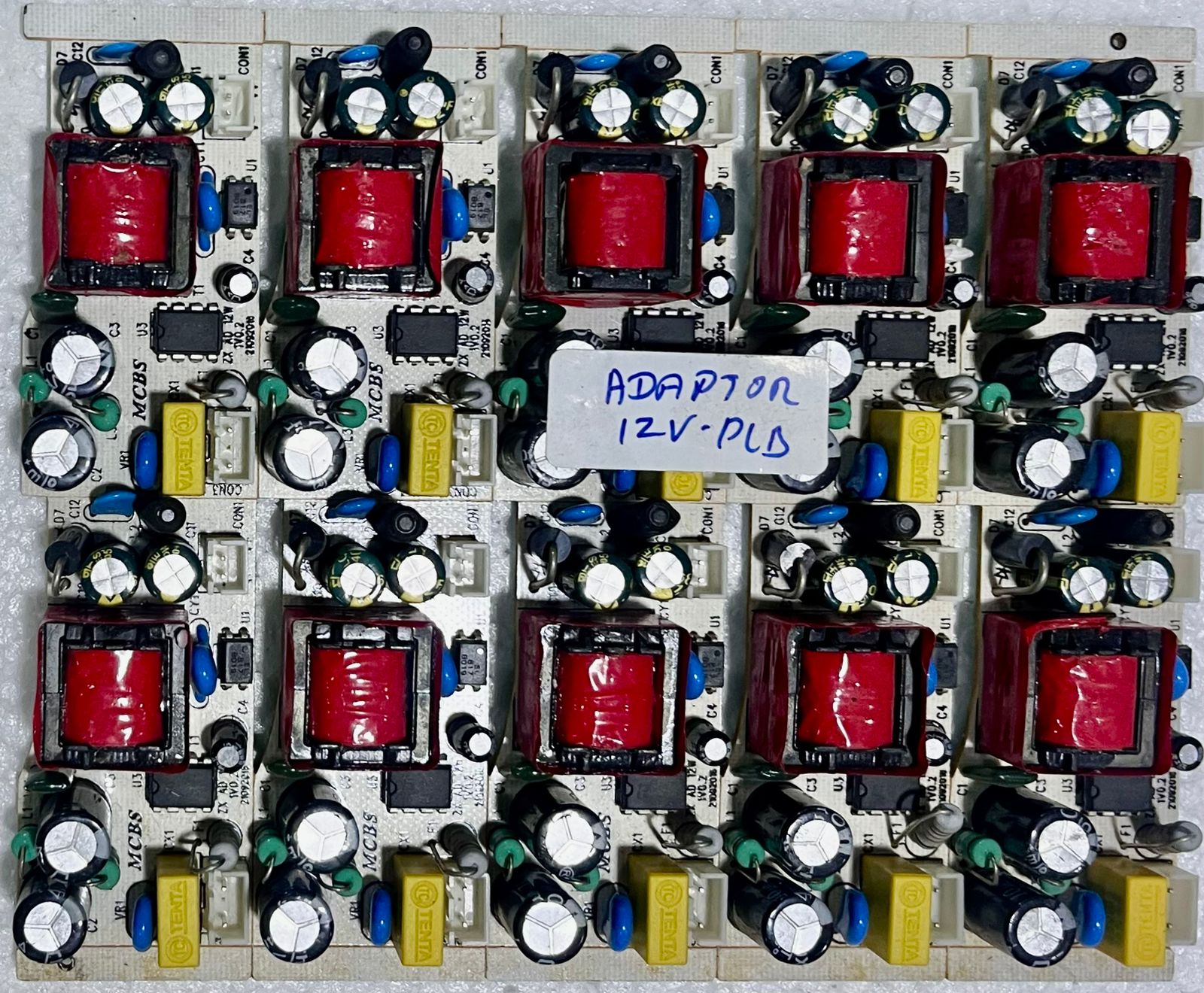

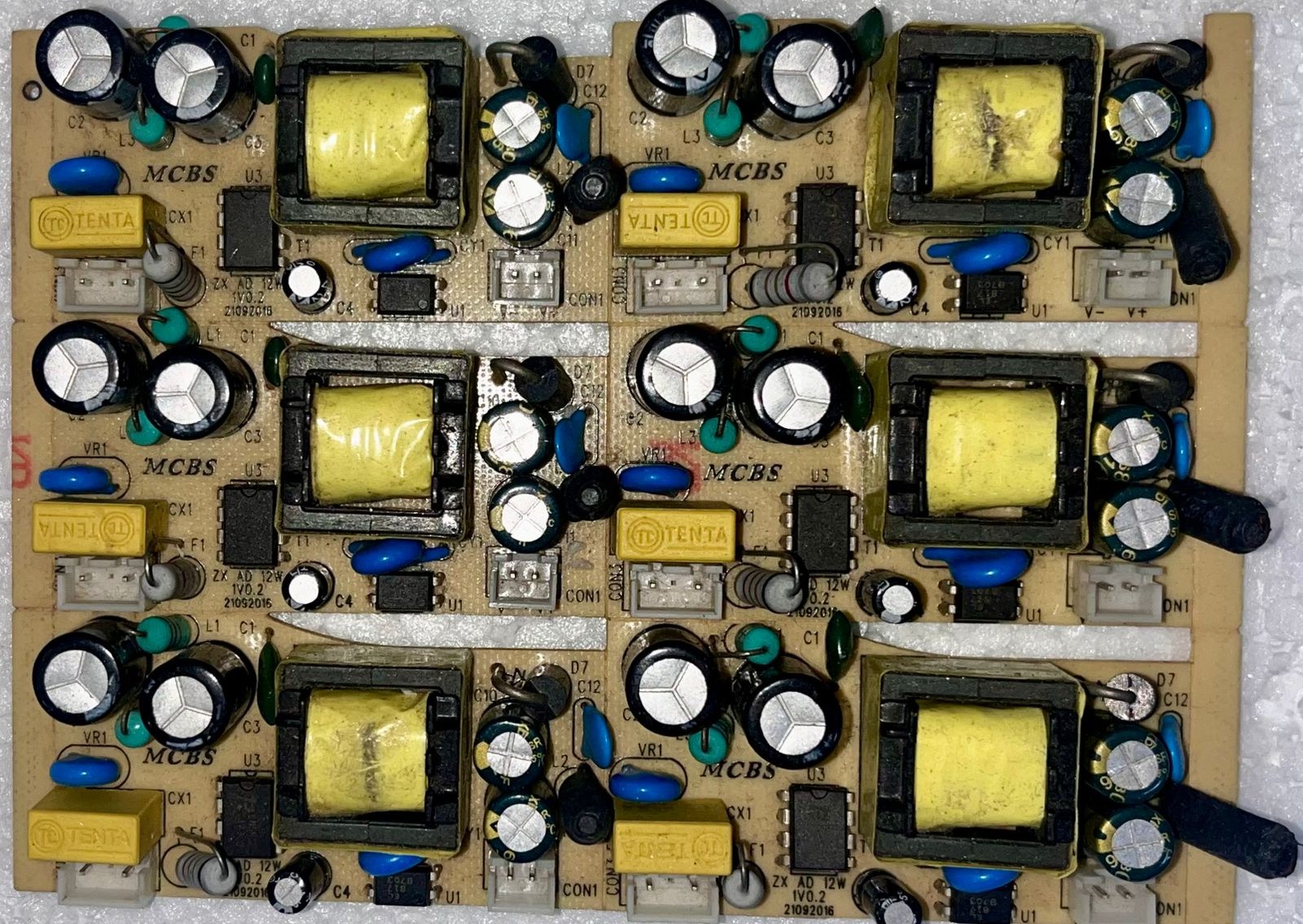

Wave Soldering / Through-hole (TH) Technology

PCB Assembly services in the through-hole arena are many. Our expertise with Axial, Radial, DIP, Right Angle connectors, Header connectors, SIP sockets, to name a few that we work with daily.

MCBS-EMS provides Wave Soldering and through-hole PCB assembly jobs for a veriety it PCBs. It has a complete set up to carry out TH and MI based PCB assembly

Wave Soldering is a built soldering process that enables one to many Circuit boards in a short amount of time.

It works by passing each Circuit board over a pan of melton solder. A pump in the pan creates a Wave of solder that washes over the board and there by soldering the components to the board.

MCBS-EMS is fully equipped with high tech Wave soldering M/cs to carry out the jobs. MCBS-EMS has a each complete set up with conveyor system, control mechanism, collng fans and power system. brief details of the system is given here

A. Conveyor - Finger Conveyor With Titanium Finger

- Manual Conveyor width adjustment from 70 mm to 300 mm

- 300 mm PCB input chain type Conveyor extension as standerd

- Finger cleaning device with solvent tank as standard

B. Control - PLC control with individual PID control for solder pot & each preheater

- 5.7" Touch panel display control

- Profile storage for 99 PCB thru USB stick

- Management and Machine data realtime storage thru USB stick

C. Cooling - Cooling fan at exit

D. Power -

- 415 V, Three phase, 50 Hz, 16 KW power consumption(for O-wave pot)(22KW for dual jet wave pot)

- Highly Skilled Staff trained and certified

- Manual Through-Hole Assembly

- Customer Slide line for larger volume

- Press fit connectors

- DIP soldering

Other facilities :

There are various options available for fluxing. pre-heating, solder Pot change for RoHs work.

DIP (Pot) Soldering Facility

Prototype

Low Volume

| Bath Size | 14" x 14" | 18" * 14" |

| Solder Capacity | 35 Kg | 45Kg |

| Power Supply | 220V Ac, 50Hz | 220 V Ac, 50 Hz |

| Heater Power | 3.2 Kw | 4.0 Kw |

| Heat-up Time | 35 minutes | 35 minutes |

| Bath Depth | 50 mm | 50 mm |

| Dimensions | 690 mm x 460 mm x 360 mm | 790 mm x 460 mm x 360 mm |

| Weight Without Solder | 46 Kg | 50 Kg |

Hand Soldering Facility

MCBS-EMS has a complete set up with soldering station, rework station, inspection gedgets to carry out manual soldering PCB Assembly